Dairy Accessories

Dairy accessories are a broad range of tools and components used to support daily operations in dairy farms and processing plants. These accessories help improve milking efficiency, animal comfort, hygiene, and milk quality control. Here’s a breakdown of the most commonly used ones:

Actuatorwith TC-End

| Design Type | Pneumatic or Electric Actuator with Tri-Clamp (TC) end connection |

|---|---|

| Material | SS 304, SS 316, SS 316L (body and end connections – hygienic grade) |

| Operation Type | On/Off or Modulating control (single or double acting for pneumatics) |

| Connection Type | TC-End (Tri-Clamp), easy to integrate into sanitary piping systems |

| Applications | Used in Food, Dairy, Pharmaceutical, Brewery, and Chemical pipelines for automated valve control |

| Temperature & Pressure | Temp: -10°C to 120°C; Pressure: PN 6 to PN 40 depending on actuator model |

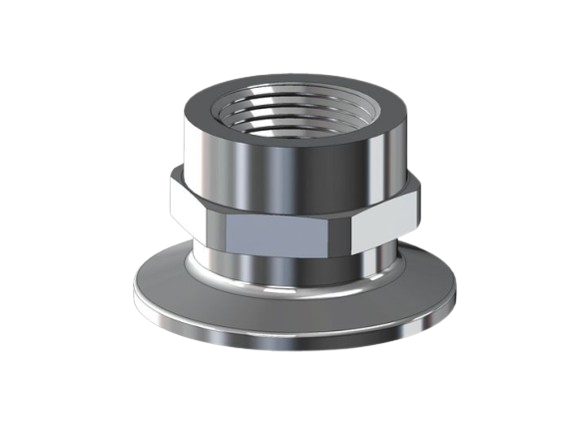

Female TC Liner

| Design Type | Female Liner with Tri-Clamp (TC) end for secure sanitary connections |

|---|---|

| Material | SS 304, SS 316, SS 316L (hygienic and corrosion-resistant stainless steel) |

| Connection End | One end female threaded (BSP/NPT/SMS), other end TC ferrule |

| Applications | Used in Dairy, Pharmaceutical, Food & Beverage, Biotech piping systems |

| Temperature & Pressure | Temperature: -10°C to 120°C; Pressure rating: PN 6 to PN 16 |

| Finish | Mirror polished inner surface for hygienic flow and easy cleaning |

Floor Drain

| Design Type | Hygienic design with removable grating and deep seal trap |

|---|---|

| Material | SS 304, SS 316, SS 316L (for corrosion and chemical resistance) |

| Outlet Connection | Bottom or side outlet with BSP/NPT/Plain/Welded/TC end options |

| Applications | Used in Food & Beverage, Pharma, Dairy, Commercial Kitchens, Clean Rooms |

| Load Capacity | Light to heavy-duty (pedestrian to equipment load bearing options available) |

| Finish | Electro-polished or matt finish, with smooth surface for easy cleaning |

Wafer Checkvalve

| Design Type | Dual plate / Single disc wafer type non-return valve |

|---|---|

| Material | SS 304, SS 316, SS 316L, Carbon Steel, Cast Iron (optional rubber/metal seat) |

| Connection Type | Fits between flanges – ANSI, DIN, JIS standards available |

| Applications | Used in Water Treatment, HVAC, Food Processing, Chemical, and Pharma pipelines |

| Pressure Rating | PN 10 to PN 40 / ANSI 150 to 300 |

| Temperature Range | -10°C to 200°C (depending on material and seat type) |

Male TC Liner

| Design Type | Male Liner with Tri-Clamp (TC) end for hygienic and leak-proof connections |

|---|---|

| Material | SS 304, SS 316, SS 316L (sanitary grade stainless steel) |

| Connection End | One end Male Threaded (BSP/NPT/SMS), other end with TC ferrule |

| Applications | Widely used in Dairy, Pharma, Food & Beverage, and Biotech pipelines |

| Temperature & Pressure | Temperature: -10°C to 120°C; Pressure: PN 6 to PN 16 |

| Finish | Mirror polished inner bore for hygienic flow and easy cleaning |

Man Hole

| Design Type | Circular or Square Manhole with hinged or bolted lid for easy access |

|---|---|

| Material | SS 304, SS 316, SS 316L, Carbon Steel (corrosion-resistant, hygienic material) |

| Size | Custom sizes available, typically ranging from 200mm to 600mm diameter |

| Application | Used in Dairy, Food Processing, Pharmaceutical, Water Treatment, and Chemical industries |

| Sealing | Gasket sealed for leak-proof, sanitary environment |

| Temperature & Pressure | Temperature: -10°C to 120°C; Pressure: PN 6 to PN 40 (depending on application) |

Mixingproof Valveweldable

| Design Type | Mixing Proof valve with weldable ends for secure, sanitary installation |

|---|---|

| Material | SS 304, SS 316, SS 316L (hygienic and corrosion-resistant stainless steel) |

| Connection Type | Weldable ends for integration into piping systems with Tri-Clamp (TC) or SMS unions |

| Applications | Used in CIP systems, mixing of different media in Dairy, Food & Beverage, Pharma industries |

| Sealing | Prevents cross-contamination by providing a bubble-tight seal between two media streams |

| Pressure & Temperature | Pressure: PN 10 to PN 40, Temperature: -10°C to 120°C (depending on material and design) |

TC Sampling Cock

| Design Type | Tri-Clamp (TC) connection with manual or automated sampling mechanism |

|---|---|

| Material | SS 304, SS 316, SS 316L (hygienic-grade stainless steel) |

| Connection Type | Tri-Clamp (TC) or Welded connection for easy installation and removal |

| Applications | Used for sampling in Dairy, Food & Beverage, Pharmaceutical, and Chemical industries |

| Flow & Pressure | Flow rate: 5–30 LPM, Pressure: 1–4 bar (depending on system design and application) |

| Temperature Range | -10°C to 120°C (depending on material grade and sealing configuration) |

.png)

Tube Expander

| Design Type | Manual or Pneumatic Tube Expander used for expanding tubes to fit into tube sheets or other fittings |

|---|---|

| Material | Carbon Steel, SS 304, SS 316 (for strength and durability) |

| Application | Used in Heat Exchangers, Pressure Vessels, Boilers, and other systems requiring tube fitting or expansion |

| Range | Expands tubes from 1/4" to 2" in diameter (custom sizes available) |

| Working Pressure | Works under pressures up to 2500 psi depending on the tool and design |

| Temperature Range | Suitable for temperatures up to 300°C, depending on the material and application |

Syphone Cock

| Design Type | Syphon Cock with manual or automatic valve for controlling flow in siphoning systems |

|---|---|

| Material | SS 304, SS 316, SS 316L (hygienic and corrosion-resistant stainless steel) |

| Connection Type | Tri-Clamp (TC) or BSP/NPT thread connections for secure fitting |

| Applications | Used in Dairy, Food & Beverage, Pharmaceutical, and Chemical industries for precise fluid control |

| Flow & Pressure | Flow rate: 5–20 LPM, Pressure: up to 4 bar (depends on system and application) |

| Temperature Range | -10°C to 120°C (depending on material grade and application) |

.png)

TC HoseNipple

| Design Type | Hose Nipple with Tri-Clamp (TC) end for secure and leak-free connections |

|---|---|

| Material | SS 304, SS 316, SS 316L (corrosion-resistant, hygienic-grade stainless steel) |

| Connection Type | Tri-Clamp (TC) on one end, other end with BSP/NPT/Plain threads for hose connection |

| Applications | Used in Dairy, Food & Beverage, Pharmaceutical, and Chemical industries for fluid transfer |

| Size Range | Available in sizes ranging from 1/2" to 4" NB (custom sizes available) |

| Temperature & Pressure | Temperature: -10°C to 120°C, Pressure: PN 6 to PN 16 depending on material and application |